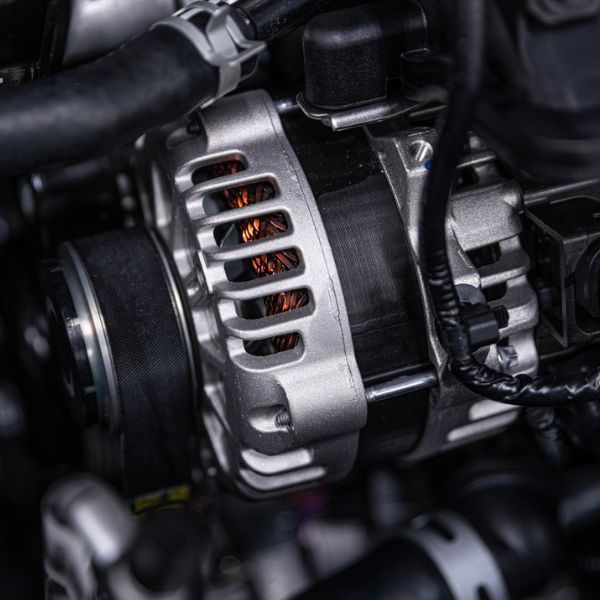

The alternator is a crucial component of your vehicle's charging system, responsible for generating electrical power to recharge the battery and power various electrical systems. When signs of alternator failure emerge, such as dimming lights or a dead battery, it's essential to prepare your vehicle thoroughly for an alternator replacement. Learn practical steps to ensure a smooth and successful alternator replacement.

Important steps to ensure a perfect alternator replacement

Step 1: Diagnose the Alternator -- Before diving into the replacement process, it's crucial to confirm that the alternator is indeed the culprit. Common signs of a failing alternator include dimming headlights, a warning light on the dashboard, and difficulty starting the vehicle. Use a multimeter to check the voltage across the battery terminals with the engine running. A healthy alternator should produce a voltage reading between 13.5 and 14.5 volts. If the reading is lower, it's likely that the alternator is failing and needs replacement.

Step 2: Gather Necessary Tools and Parts -- Once you've confirmed the need for an alternator replacement, gather all the necessary tools and replacement parts. Typical tools include a socket set, wrenches, a serpentine belt tool (if required), and a vehicle-specific repair manual for reference. Ensure you have the correct replacement alternator for your vehicle and consider replacing the serpentine belt if it shows signs of wear.

Step 3: Disconnect the Battery -- Safety should always be a top priority when working on a vehicle's electrical system. Begin by disconnecting the negative terminal of the battery to prevent any electrical accidents during the replacement process. This simple step ensures your safety and prevents damage to electrical components.

Step 4: Locate the Alternator: -- In most cases, the alternator is positioned at the front of the engine and is connected to the engine block by bolts. It may also be connected to the serpentine belt system, requiring additional steps for removal.

Step 5: Remove the Serpentine Belt -- If your vehicle's alternator is connected to the serpentine belt, use the serpentine belt tool to release tension and remove the belt from the alternator pulley. Make note of the belt's routing or refer to the diagram under the hood for future reference. This step ensures a smooth reinstallation of the serpentine belt after the alternator replacement.

Step 6: Disconnect Electrical Connections -- Carefully disconnect all electrical connections to the alternator, including the positive and negative terminals. Some vehicles may also have a wiring harness or connector that needs to be detached. Take note of the connections and their locations to simplify the reinstallation process.

Step 7: Remove Mounting Bolts -- Use a socket set to remove the mounting bolts securing the alternator to the engine block. Keep track of the bolts and their locations, as they may vary in size. Once the bolts are removed, gently wiggle the alternator to detach it from the mounting bracket.

Step 8: Compare Old and New Alternators -- Before installing the new alternator, compare it to the old one to ensure they are identical. Check for any noticeable differences in design, connections, or pulley size. This step is crucial to avoid installation issues and ensure compatibility with your vehicle.

Step 9: Install the New Alternator -- Position the new alternator in place and secure it with the mounting bolts. Tighten the bolts according to the specifications provided in your vehicle's repair manual. Reconnect the electrical connections, ensuring a snug and secure fit.

Step 10: Reinstall the Serpentine Belt -- If your vehicle uses a serpentine belt, use the serpentine belt tool to release tension and reinstall the belt onto the alternator pulley. Ensure the belt is correctly routed according to the diagram or markings under the hood.

Step 11: Reconnect the Battery -- With the alternator securely installed and all electrical connections in place, reconnect the negative terminal of the battery. This step re-establishes power to the vehicle and allows you to test the new alternator.

Step 12: Test the Alternator -- Start the vehicle and use the multimeter to check the voltage across the battery terminals with the engine running. A healthy alternator should now produce a voltage reading between 13.5 and 14.5 volts, confirming the success of the replacement.

Achieving a successful alternator replacement

Of course, every alternator replacement will vary somewhat based on the make and model of your vehicle. But by following these steps, you have a good basic overview of what usually needs to happen for a successful replacement. Alternator replacements can be successfully accomplished by people with a moderate level of mechanical experience. By doing the job yourself, you can save on the cost of labor.

Related Articles

5 Times to Upgrade to a High Output Alternator

Why My Alternator Died So Quickly

5 Times a Wire Alternator is a Good Choice